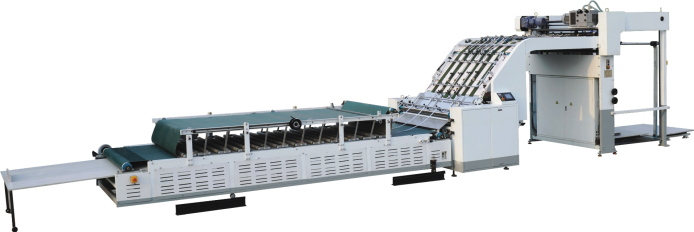

BLSA II-1300 / 1450 Lamitac Lamination Systems. Lithotype / flute Laminator

BLSA Series Flute Laminating Machine is used to paste the color-printing surface paper together with the bottom paper (cardboard corrugated sheet) accurately. The pasted paper is smooth, stiff and with high precision .This machine is easy to operate, which is an ideal necessary equipment for high-grade color -printing packing manufacturers. Lamitac series machines have been acceptable for the customers from home and abroad due to their outstanding features, high quality and good service.

Other Parts:

| No. | Name | Specification | Manufacturer | REMARKS |

| 1 | Contactor | LC1-D0910 | SCHNEIDER | |

| 2 | Stabilized voltage supply | S-250-24 | MEANWELL,TAIWAN | |

| 3 | PLC | FX1N-60MT | MITSUBISHI, JAPAN | |

| 4 | PLC extension | FX2N-2DA | MITSUBISHI, JAPAN | |

| 5 | Approach switch | PM12-02N | FOTEK, TAIWAN | |

| 6 | Vari-speed drive | FR-E540-2.2K | MITSUBISHI, JAPAN | |

| 7 | Photoelectric switch | E2R-10N | FOTEK, TAIWAN | |

| 8 | Encoder | E6B2-CWE6C | OMRON, JAPAN | |

| 9 | Thermal relay | LR2-D1310N | SCHNEIDER | |

| 10 | Touch screen | MT506S | EVIEW, TAIWAN | |

| 11 | Step motor | 2S86Q-030B8 | KINCO, SHENZHEN | |

| 12 | Step drive | 2M1160 | KINCO, SHENZHEN |

| MODEL | BLSA-II 1300 | BLSA-II 1450 |

| Max Paper Size ( L x w ) | 1300 x 1300mm | 1450 x 1300mm |

| Min Paper Size ( L x w ) | 400 x 400mm | 400 x 400mm |

| Laminating Precision | ≤±1.5 | ≤±1.5 |

| Speed | 100 sheets / min | 100 sheets / min |

| Total Power | 13.5 KW | 13.5 KW |

| Overall Dimensions | 14000 x 2300 x 2700mm | 14300 x 2450 x 2700mm |

- production up to 6,000 sheets per hour

• short make ready times (set-up)

• little maintenance requirement

• just a very few wearing parts

• easy machine operation

• high reliability and availability of the machine

• reliable sheet mounting registration system

• minimum glue application, for producing flat sheets

• simple and fast wash-up of the glue rollers – using tools

• equipped a well proved suction belt feeder for carrier sheets

• fully developed turning and conveyor system, non-stop type for just mounting a few samples

- 1) BLSA II Series Automatic Flute Laminator adopts unique pressing spring front lay registration design compliant with PLC control system which makes machine run at high lamination precession and low rate of breaking down.

2) The machine uses speed variators, PLC central control, simulation to digit program system. The core designed rubber roller together with knurled steel roller enhances the evenness of gluing, strength of stickiness, as well as bringing down the cost of production.

3) Balance-tested rollers, tight assembling technique, plus timing belts driving mechanic system makes the machine runs at low noise with high precision.

4) The machine adopts automatic glue supply and recyclable glue circulating system.

5) Self-developed high-strength feeder compliant with high configuration electric system makes the machine run at low malfunction. The electric parts used are all world wide available brand or well-known Chinese brand.

6) All material bought from outside are inspected according to ISO-9001 standard and the key parts such as bearings are imported ones.

7) The bottom sheet for this machine can be A, B, C, D, E, F flute corrugated sheet. It can do3 ply board to sheet lamination. The range for top paper can be 180-600 GSM with top paper advance or alignment function.

8) Less vibration and low noise.

9) Gluing even: 30-50gsm. Quite cost effective for your production.

10) Side lay registration is installed on the machine.

11) The belt of the conveyor is SIGLING, the vacuum feeding belt is Nita, The timing belt is GEIZE; The bearings in Key parts are UBC or IKO