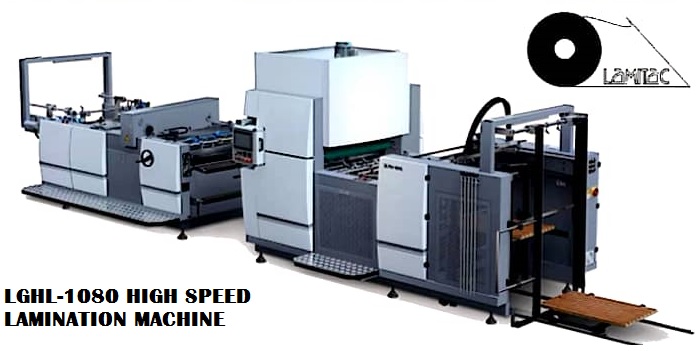

LGHL-1080 High Speed Lamination Machine

High grade Lamitac brand film laminating machine, has realized centralized display control, PLC information processing, applications program calculation, This laminating equipment, make operation become simple, make function by itself, to enhance efficiency, can reflect value.

Our designers also paid special attention to human body engineering and shape design. Soft thinking generated flexible designing, make ice-cold machine more streamlined dynamic, infinite vitality and vigor, more in line with the spirit of modern industrial workers, let them work happy, send out more energy.

LGHL is a water-based laminating and Thermal laminating machine as one of the multi-model has a machine control integration, environmental protection energy-saving, high efficiency. User-friendly design of the new laminating machine-widely used textbooks, books and other publications, wall printings, bag, box etc and color printing rear Surface. This machine adopts frequency control, PLC centralized control, man-machine interface display by automatic feeding machine, the former regulation, pull gauge, round brush and oil hot rollers in addition to powder, film feeding, glue coating mechanism, automatic tension control mechanism for the film, the film cutting and perforating unit complex and complex clutch control system helps to avoid production includ.

| Specifications | LGHL-1080 | ||

| Max. Paper Size: | 1080 x 820mm | Lamination Calendar | Oil |

| Min. Paper Size: | 320 x 320mm | Drying System | Hot Air |

| Mechanical Speed: | 40 – 80m/min | Cutting System | Fly Knife, Rotary Knife & Easy Pull System |

| Paper Weight: | 105-500g/m2 | Pressure | 5 – 9mpa |

| Width of Lamination Roller: | 1060mm | Voltage | 380V-3ph-50Hz |

| Diameter of Lamination Roller: | 450mm | Power | 68-75KW |

| Lamination Film Roll Core Dia: | 6 inch | Dimensions | 9800 x 1900 x 2600 |

| Temperature: | 85 – 125 Degrees | Weight | 7000Kg |

LGHL is a water-based laminating and Thermal laminating machine as one of the multi-model has a machine control integration, environmental protection energy-saving, high efficiency. User-friendly design of the new laminating machine-widely used textbooks, books and other publications, wall printings, bag, box etc and color printing rear Surface. This machine adopts frequency control, PLC centralized control, man-machine interface display by automatic feeding machine, the former regulation, pull gauge, round brush and oil hot rollers in addition to powder, film feeding, glue coating mechanism, automatic tension control mechanism for the film, the film cutting and perforating unit complex and complex clutch control system helps to avoid production includ.